All India Rubber Industries Association (AIRIA) is successfully running Knowledge Series - Rubber & Beyond, which is and insight into the understanding of technology and its applications from leading experts and thought leaders in the Rubber Industry. The series aims to provide insights into this technical subject relevant to the rubber sector. The latest webinar on "Application of Fatigue Failure Studies in the Rubber Industry" featured Dr. Pullela Mythravaruni, Assistant Professor, Rubber Technology Centre, IIT Kharagpur, discussing the behavior of rubber under cyclic stress and fatigue failure mechanisms across various industries.

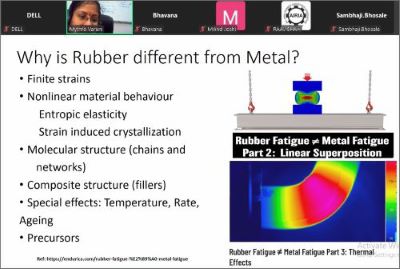

The webinar covered key differences between rubber and metal fatigue behavior, including material parameters and environmental factors, along with various testing methods and life prediction approaches for both strain-life and crack growth methodologies.

Milind Joshi, Committee Member, AIRIA Western Region, introduced the speaker.

Dr. Pullela Mythravaruni discussed the importance of studying fatigue failure in rubber components across various industries. She explained that fatigue studies are crucial for safety, reliability, and optimizing design and material selection and highlighted key differences between rubber and metal fatigue behavior, including the effects of mean stress/strain, linear superposition, and thermal conductivity and introduced the concept of tearing energy and its role in rubber fatigue analysis, as well as the effects of different material parameters and environmental factors on fatigue performance.

She explained that there are two main methodologies: strain life method and measuring fatigue crack growth. The strain life method uses S-N curves to relate strain amplitude to cycles to failure. For varying temperatures and load spectra, approaches like the Arrhenius function and Miner's rule can be used. To analyze random loading, techniques like hysteresis filtering, peak valley filtering, discretization, and rainflow counting are used to convert to a deterministic spectrum. For crack growth based methods, the tearing energy is calculated for different deformation modes and used in models like Paris law. She also mentioned finite element simulation approaches for low and high cycle fatigue in software like Abaqus. Overall, the presentation covered both experimental and modeling techniques for predicting rubber fatigue life.

The session also focused on the fatigue failure studies in rubber components. She emphasizes the importance of integrating fatigue failure analysis into quality control and product development to prevent machinery failures and accidents and highlighted the potential for enhancing predictive maintenance strategies using real-time monitoring techniques and adopting eco-friendly rubber composites for improved durability and reduced carbon footprint.

At the end of the session she stressed the importance of collaboration between industry and academia to foster innovation in developing sustainable rubber composites with better fatigue resistance.

The session was attended by 150+ participants and the next session will be conducted soon.