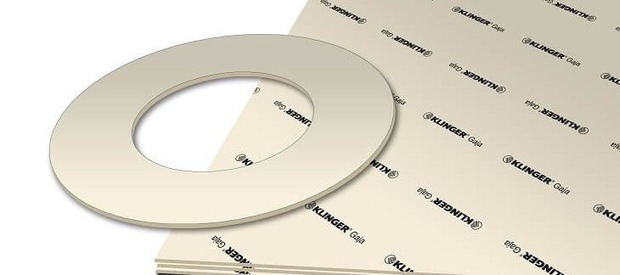

Klinger Dichtungstechnik has launched an eco-friendly gasket with the bold claim that the product line is set to redefine the industry's approach to sustainability. Introduced in early May, the Gaja gasket is the result of extensive R&D to enable the incorporation of "the highest possible number of renewable raw materials", said the Austrian manufacturer.

Reviewing the R&D effort, Stephan Piringer, head of product engineering, said an analysis found that much of the carbon footprint of Klinger's products was due to how and where raw materials were sourced.

"To reduce this footprint, it was evident that we needed to focus on sustainable sourcing" rather than on the manufacturing processes, Piringer said. Klinger, therefore, increased its focus on driving sustainability along its supply chain while increasing its use of renewable resources to reduce product carbon footprint. A fiber-reinforced gasket essentially consists of a blend of fibers, elastomers, mineral fillers with other components, according to Piringer.

"We have worked to replace each of these components with sustainable alternatives: for example, using natural rubber instead of synthetic rubber and renewable fibers instead of synthetically produced ones", he added. Also, according to the Klinger manager, a "particularly innovative component is bio-circular silica, which is derived from rice waste, making it particularly eco-friendly".

Regarding technical performance and durability, Piringer said it is important to consider that many Klinger products are specially designed for certain applications and operating conditions such as temperature and media. Gaja, on the other hand, offers a "general, sustainable" option, Piringer said. "It required a lot of experience, patience and experimentation, but in the end, we developed a sustainable and high performing sealing solution".